Passive fire protection is an essential aspect of gypsum construction. Gypsum firewalls of various types (shaft walls, simple partitions, etc.) prevent fire from spreading without relying on mechanical means of control, such as sprinkling. The fire-resistant properties of gypsum, in addition to ease of gypsum panel installation, has made gypsum panels ubiquitous in construction.

Gypsum area separation firewalls have been constructed for more than 35 years and are an excellent way to separate dwelling units in multi-unit residential construction—referred to as “townhouses” in the residential code. The panels are compatible with a variety of wall framing systems. The ease of construction makes these walls more time, labor, and cost efficient than other technologies such as masonry. Also, gypsum shaftliner firewalls can be installed year-round without costly cold weather provisions for drying because there is no mortar to freeze.

Combine these multiple advantages with the fact that such assemblies offer the code required two-hour fire separation and code compliant sound transmission class ratings in excess of 60, and gypsum ASWs become the preferred choice over other technologies.

The typical ASW consists of:

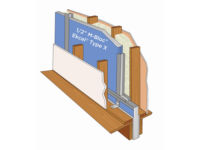

A central wall consisting of two 1-inch (25.4 millimeters) type X gypsum shaftliner panels inserted between steel H-studs and rated for two-hours per ASTM E119, UL 263 or Section 703.3 of the International Building Code.

A non-fire-resistance rated flanking wall on both sides attached to the steel H-studs via aluminum breakaway clips set a minimum of 3/4 inch (19 millimeters) off the central wall. The flanking walls consist of minimum 1/2-inch (12.7 millimeters) gypsum panels attached to minimum nominal 2x4 wood studs or minimum 15 mil 35/8-inch steel studs.

Classify Information

Unfortunately, the International Residential Code does not clearly classify ASWs and fails to specifically define them in the code. Section R302.2 of the IRC recognizes two types of separations between townhouse dwelling units—double walls and common walls. Double walls are defined in section R302.2.1 of the IRC, which states, “Double walls. Each townhouse shall be separated by two 1-hour fire-resistance-rated wall assemblies tested in accordance with ASTM E119, UL 263 or Section 703.3 of the International Building Code.”

As the name suggests, double walls consist of two, one-hour framed walls back-to-back that, combined, provide a two-hour separation. Per the IRC, common walls are single framed walls that may be one-hour rated (if the units have sprinklers) or two-hour rated if unsprinkled. ASWs are often classified by code officials as common walls, though, as will become clear, they are unique and do not resemble typical common walls.

Regarding common walls: Section R302.2.2 of the IRC reads, “The common wall shared by two townhouses shall be constructed without plumbing or mechanical equipment, ducts or vents in the cavity of the common wall. The wall shall be rated for fire exposure from both sides and shall extend to and be tight against exterior walls and the underside of the roof sheathing.” Penetrations in common walls are expressly prohibited because nothing can be allowed to compromise the integrity of the fire-resistant barrier shared between the units.

Utility placement behind the flanking walls of an ASW fire wall system has become a difficult issue. The double wall design can accommodate utilities such as wiring and HVAC ducts in the walls penetrating into the individual dwelling spaces. Common walls, since they are shared, cannot per section R302.2.2 of the IRC. Again, because code officials can interpret ASWs as a variant of a common wall, there is much confusion over whether the flanking walls of the overall ASW assembly can be penetrated or have utilities or not.

Engineering and Code Evaulation

Recently, the Gypsum Association obtained an engineering and code evaluation regarding utilities and the flanking walls of ASW assemblies. That evaluation is available at gypsum.org, under Technical Resources, Engineering Reports/Code Acceptances. Look for “Engineering Evaluation: Utilities in the Flanking Walls of Gypsum Area Separation Fire Walls.”

The evaluation report details the uniqueness of the ASW and what characteristics of the system reflect a common wall and what characteristics do not. The report concludes that the central wall of the ASW, i.e. the shaftliner wall, serves as a “common wall.” The flanking walls, on the other hand, are not common to the adjacent units, but instead are individual to them. Therefore:

The central wall shall not be penetrated by any mechanical, plumbing, etc. systems or components.

The non-fire-resistance rated flanking walls shall be permitted to be penetrated as needed to allow for utilities, ducts, or vents in the wall cavity.

In summary, the flanking walls are not common elements and can therefore have mechanical and other components and penetrations as needed.

When considering gypsum ASWs keep the following in mind:

- Gypsum Area Separation Firewalls are specifically designed to be 2-hour walls separating townhouses and areas in various occupancies. They are not intended for use as shear walls.

- Gypsum Area Separation Firewalls are designed to be laterally supported with aluminum clips spaced at specified intervals. Consult the manufacturer for specific clip placement and maximum allowable wall heights.

- Penetrations and openings in Gypsum Area Separation Firewalls are not addressed in this document.

- Do not install insulation in the wall system until the building has been properly closed or dried in.

- The exterior side of Gypsum Area Separation Firewalls, including offsets, parapets and wall extensions (wing walls), must be protected by appropriate weather resistant materials.

- Gypsum panels shall not be used where there will be direct exposure to water or continuous high humidity conditions. Gypsum panel products shall not be installed in direct contact with concrete, masonry, or other materials that have high moisture content.

- Gypsum panel shall not be used where they will be exposed to sustained temperatures of more than 125 degrees Fahrenheit (52 degrees Celsius) for extended periods of time.

For more information on gypsum area separation walls, including how they are constructed, visit the GA’s Publications-At-A Glance webpage for the free publication GA-620 Gypsum Area Separation Firewalls. GA-620 details installation of ASWs as well as proper handling and storage of shaftliner panels. Information and illustrations in situ explaining the use of shaftliner in multi-family and commercial construction are available on gypsum.org’s Special Performance Gypsum Panels page, which can be found under the Technical Resources section.

Of course, there are many uses for gypsum shaftliner panels aside from ASWs. As the product name suggests, shaftliner panels are excellent for shafts of all types (elevator, utility, etc.). Area separation fire wall and shaft wall designs can be found under their respective sections of the GA-600 Fire Resistance and Sound Control Design Manual, available for purchase at the GA Bookstore online.

Report Abusive Comment