As a Mexican architect, I had the opportunity of being involved with projects in Mexico (Mexico City) and the U.S. (Hawaii, California, Arizona and Colorado) and I can tell you, construction is not the same around the world. Construction techniques and practices diversify and are not only different with the installers themselves, but also with the country’s technology and development—it is impressive how just crossing over the border is a colossal change.

Take Calexico, California and Mexicali, Mexico, as an example: same weather conditions, same topography and geography, and even the same manpower.

Hispanic installers have a strong presence in the U.S. drywall industry. Most used to live in Mexico. A few might have a bachelor’s degree as engineers, architects, accountants, etc., from their country and they have learned the drywall techniques by practicing trial and error, or a family member introduced them to the trade. It is not unusual to find more than one family member working on the same jobsite.

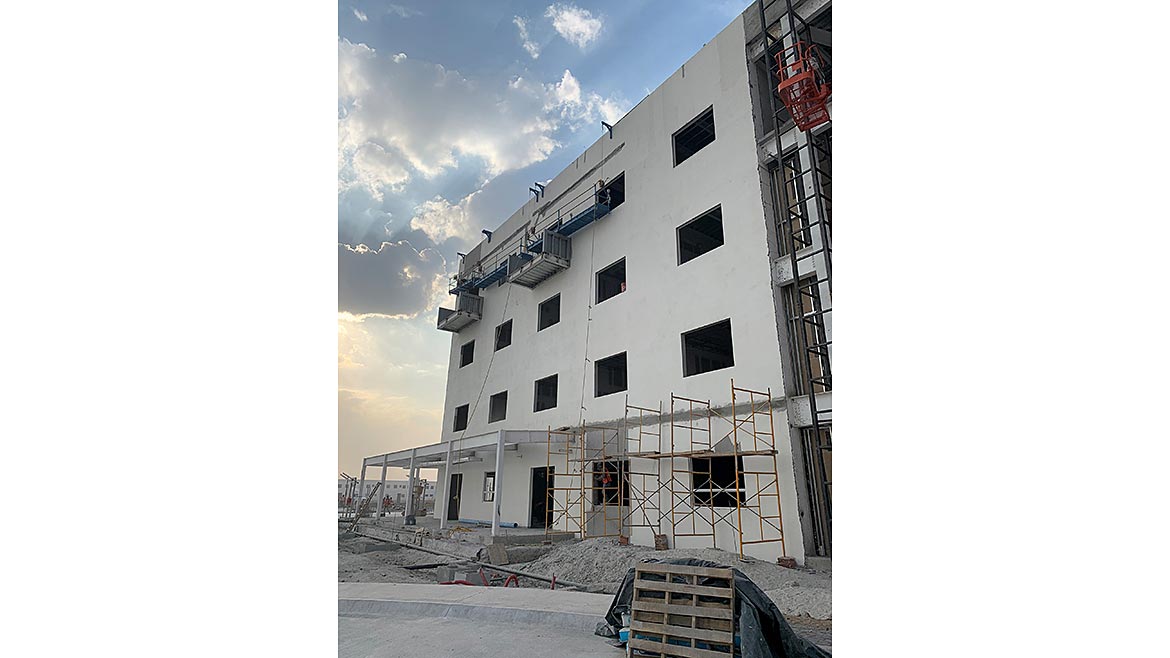

In Mexicali, a one-story house is built the following way: Concrete, blocks and steel bars for structure is the most known construction system or traditional method. Contractors buy the materials (drywall/finish accessories) as they use it on the same day.

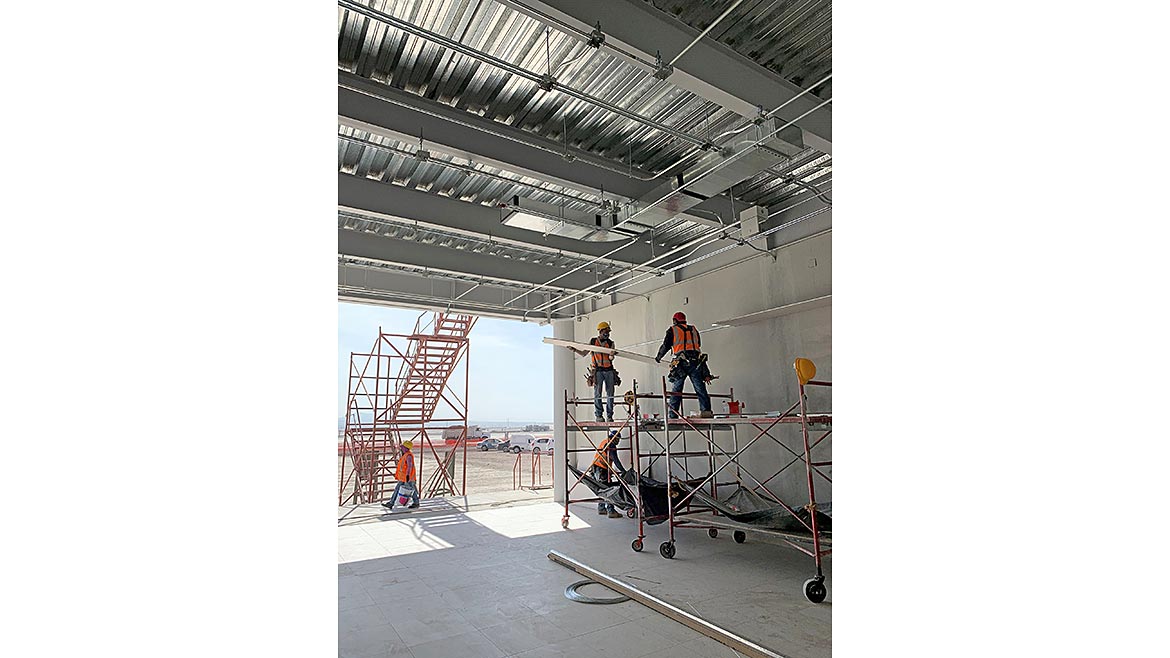

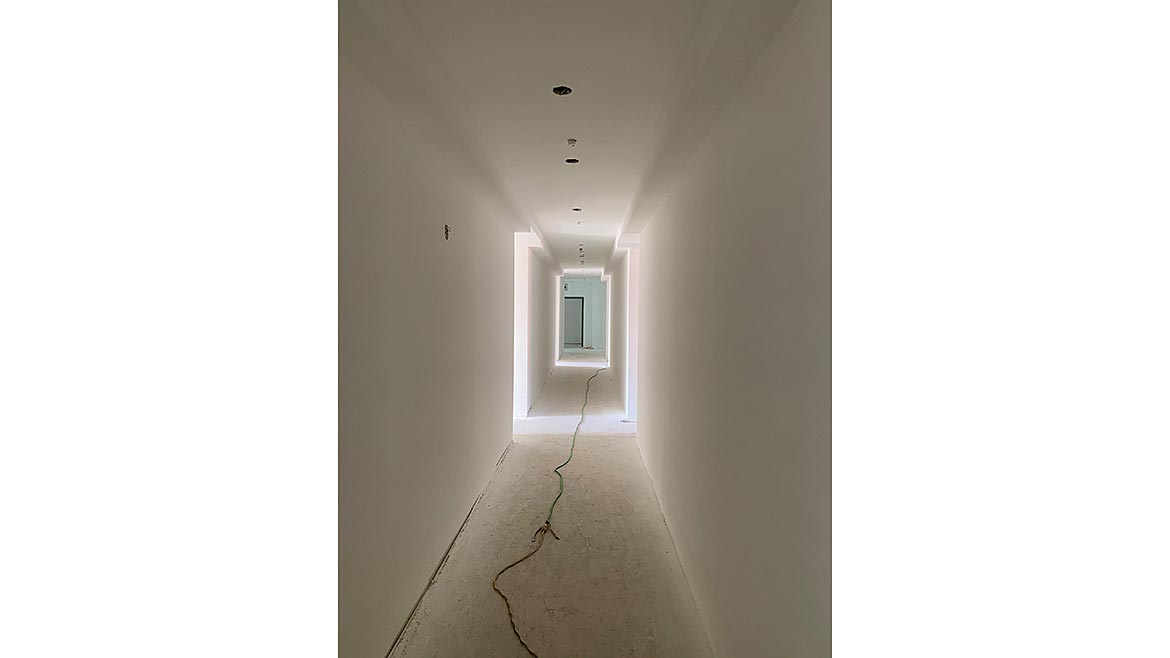

They install the light gauge metal studs and tracks onto concrete walls and ceilings and hang the drywall. Metal framing is the most common and practiced framing type in Mexico, proceeding with the taping process and with a mud pan; knives applying the first and second coats with no machine tools. Then, they apply some primer and finally paint, (no insulation needed most of the time) and surprisingly the same person does all of this (in stages).

Different Regional Practices

While in Calexico or San Diego just miles away, construction is another world. It all begins with the construction supply store, where many products are delivered to the jobsite. Whether using lumber or steel as a structural method, plumbing and electrical are already installed on pre-assembled wall frames. Most of the time, contractors know the number of drywall sheets per square footage; they also suggest the number of finishing tools that will be needed. Advanced taping tools in the U.S. would be a dream for a taper in Mexico (i.e., mud pumps, bazookas, boxes, angle heads, sanding machines).

Finishing is also related to this huge contrast between the countries’ practices and makes more sense if we analyze it. In the Southwest U.S. as an example, the three most common finishes are: paint over Level 5, Skip Trowel Texture, and high control texture on interiors; while in Mexico it is typically a coat of paint applied to stone and ceramic tiles.

What all of this is telling us, is that even society somehow is involved in this; the workforce spends more time on the construction sites than with their families. As an architect seeing this contrast on the jobsites, one thing is clear: they do need products that will make their working day easier. Tools that are easy to operate; construction industry and factories must keep innovating and improving systems, tools and products.

Images courtesy of Panel Rey.

A Hard Day’s Work

A jobsite work day is harder and more physical than other jobs. Construction industries and factories must keep innovative processes; also this can be reflected by money - it is not the same having a crew of 10 people working eight hours a day to finish a project, as it is the same crew of 10 working six hours and fewer days to finish the same project on the payroll.

How a minor change, such as advanced taping tools on the other side of the border, can have such a significant impact for workers doing the same job is astounding. Or how a small improvement on a tool or product can positively affect the workday making it easier to work with. Not all the architects, owners or even supervisors realize how hard the conditions are at the jobsite, working in 116 degrees Fahrenheit for eight or 10 hours.

What we can do is try to facilitate the process, trying not to think how to earn more money in our pockets when we can give the contractors proper tools and quality materials to save time and money. Keep asking for the latest innovations in the industry, keep doing weekly team meetings from the supervisor to the taper, and most important, it does not matter what country we are building in if we all treat each other as equals.

Report Abusive Comment