The highest expression of the plasterer’s art has been created, lost and rediscovered. Yet, for the past two millennia, Scagliola has never ceased to fascinate nor witness its aura of mystery diminish.

Part sculpture, part science, the sophisticated process that gives birth to Scagliola demands the focused mind and precision of a chemist, the hands of an experienced plasterer and the subtle, sensitive eye of an artist.

History

Scagliola results from a meticulously programmed sequence of tinting, blending and arranging plasters to imitate marble. Archaeologists have discovered that the Romans and the Egyptians employed methods, long since forgotten, to imitate marble in plaster.

However, it was in the late 16th century Renaissance that the contemporary approaches to Scagliola were conceived and perfected to effect intarsia, complicated inlays in furniture surfaces that mimicked the costly marble inlays, pietra dura, that were en vogue amongst the aristocratic courts of the day. Where precisely Scagliola making re-emerged is a point of some controversy; however, it can be narrowed down to one or the other side of the present day Italian and Austrian border, where the tradition continues in unbroken succession.

By the early Renaissance, many desired marbles were rare or had been exhausted. Scagliola could imitate such marbles as well as create colors and patterns that were not to be found in nature. The use of Scagliola soon expanded to casting in ornament, column shafts and even entire walls, the latter a process that became known in Italy as Stucco Marmo.

The use of Stucco Marmo expanded throughout continental Europe and finally to Britain in the 18th century. Prominent uses of the Stucco Marmo form of Scagliola in England include column and pilaster shafts at Buckingham Palace and the Syon House, designed by the famous architect Robert Adam. A significant breakthrough in plaster technology was achieved in the mid-19th century with the advent of Keene’s cement, which, in spite of the name, is a type of gypsum plaster so named because its compressive strength resembles that of natural cements. Keene’s cement paved the way for a new method for producing Scagliola called Marezzo, known in the United States as American Scagliola due to its ready acceptance and prominent use from the mid 1800’s until the Great Depression.

There are countless recipes, historical and contemporary, in all cases secret and proprietary, for the ingredients and mixing of Scagliola. Let’s attempt to at least partially pull back the curtain of secrecy with a basic explanation of Scagliola manufacture.

Manufacture

Traditional Scagliola can be done in situ (in place) or on a bench. Work performed in situ requires several precautions in preparation of the substrate. In all cases, the work environment should be clean, warm and dry.

Finely ground Plaster of Paris is used as the base material. Animal hide glue, high in collagen, such as rabbit or isinglass, is prepared the day of manufacture to retard the plaster and add strength to the work. Dry mineral pigments can be introduced directly into the dough, mixed with dry gypsum or emulsified, depending on desired effect. Optional ingredients include whiting (ground caulk) or selenite (ground gypsum) as filler, linseed oil to complement the glue as a retarder and aid in workability, and marble chips for decorative effect.

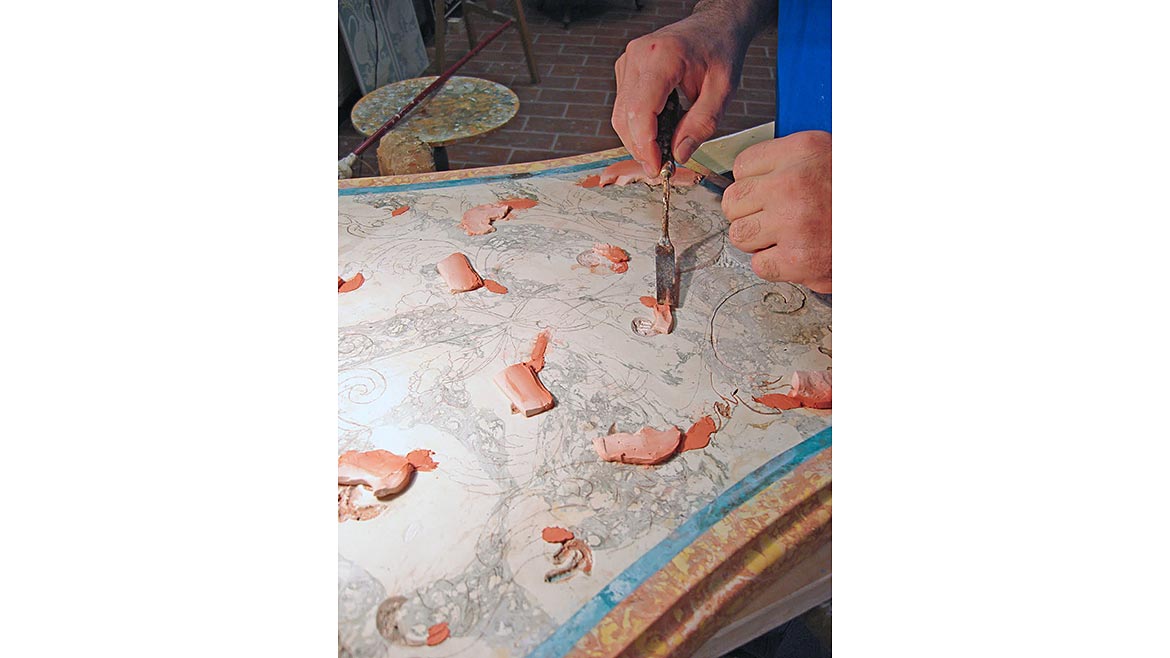

Much like a bread maker working with flour, yeast and water, the artisan kneads Plaster of Paris (molding plaster) and glue water to the consistency of firm dough. This is best accomplished by forming a ring of dry plaster surrounding a central “castle” of plaster. The moat is filled with glue water and the process of cutting and kneading begins.

Through a series of slicing, addition of pigments, folding and re-joining, the whole of the mass is mixed and set aside as large balls placed in ratios and arrangements that achieve the desired result: a counter-type of true marble or a fanciful creation. Depending on the desired outcome, from the initial mixing, colored slurries and other preparations are set aside for decorative effects. Much of the artisanship lies in a process of mental reverse engineering. One must conceive the desired outcome, have all materials on hand and systematically take steps to accomplish the effect.

Typically, the plaster is built up to 1/2- to 5/8-inch thickness, leaving 1/8-inch for cutting of the surface. Once the material has achieved an initial set, it can be planed with an appropriate cutting tool, such as a Berthelet (French razor), removing the 1/8-inch excess to realize a flat surface. At this point, the material is still malleable and can be allowed to cure as a flat panel. Alternatively, slices of Scagliola can be pressed into a mold or directly on a keyed plaster substrate in situ. For ornamental work such as balusters, urns and column shafts, the Scagliola can be wrapped around an appropriate base and turned on a lathe.

Once the Scagliola has been allowed to set and dry naturally, the work of polishing can commence. Traditionally, after cutting the Scagliola, natural pumice stones and damp sponges are used to smooth the work. The final smoothing and polishing historically was achieved with Water of Ayr, a natural snake stone from Scotland renowned principally as a hone for polishing barber straight razors. Modern polishing techniques arrive at a similar result with increasingly fine-grit wet/dry sandpaper. The finished surface can be rubbed with linseed oil to increase luster and hardness and add a measure of protection from stains.

The Marezzo plaster mix is based on Keene’s cement, a slow-setting gypsum cement that does not necessitate the use of retarders or hardeners. Silk threads are used for veining and dry mineral tints can be used to provide color.

Conclusion

Scagliola has enjoyed a rich history adorning many of Europe’s most prestigious works of architecture from the Renaissance through the Neoclassical periods. Likewise, in the 19th century and still admired in the grand entrances of courthouses, state capitols, railway stations and fine hotels across the country.

This article was co-authored with Sloan Houser and Jim Gloria

Report Abusive Comment